Optical transmission hardware integration one-stop service provider

Views: 3 Author: Tina Publish Time: 2025-02-28 Origin: Site

The main applications of photoelectric composite optical cables include communication networks, surveillance systems, smart grids, industrial automation, transportation systems, data centers, remote areas, building automation, military systems, and renewable energy systems. Their ability to integrate power and data transmission makes them a critical component in modern infrastructure and technology.

Integrated Design: Combines optical fibers and power lines within the same cable, typically with an outer protective sheath to ensure stable transmission of signals and power.

Multifunctionality: Capable of transmitting both optical signals and electrical energy, meeting diverse needs.

High Reliability: Manufactured with high-quality materials to ensure stable performance in harsh environments.

Flexibility: Can be designed with different combinations of optical fibers and power lines to suit various application scenarios.

Purpose: Used to provide both power supply and data transmission for communication base stations.

Function: Ensures stable operation of mobile networks by delivering electricity to the base station equipment while transmitting high-speed data through optical fibers.

Advantage: Reduces the need for separate power and data cables, simplifying installation and maintenance.

Purpose: Commonly used in security and monitoring systems, such as CCTV cameras.

Function: Supplies power to cameras and other monitoring devices while transmitting high-quality video signals in real time.

Advantage: Eliminates the need for separate power cords, making installation cleaner and more efficient.

Purpose: Applied in power systems for smart grid infrastructure.

Function: Transmits data for grid monitoring and control while providing power to remote devices or sensors.

Advantage: Enhances the efficiency and reliability of power distribution networks by integrating communication and power supply.

Purpose: Used in factories and industrial settings for automated machinery and control systems.

Function: Provides power to industrial equipment and transmits control signals or sensor data.

Advantage: Improves production efficiency and reduces wiring complexity in large-scale industrial environments.

Purpose: Deployed in traffic management systems, tunnel lighting, and railway communication systems.

Function: Supplies power to traffic lights, tunnel lighting, or railway signaling systems while transmitting data for real-time monitoring and control.

Advantage: Ensures reliable operation of transportation infrastructure with minimal cabling.

Purpose: Used within or between data centers for high-speed data transmission and power distribution.

Function: Supports the transmission of large volumes of data while providing power to servers and networking equipment.

Advantage: Reduces cable clutter and improves the efficiency of data center operations.

Purpose: Ideal for remote or hard-to-reach locations, such as oil rigs, wind farms, or rural areas.

Function: Delivers power and enables communication in areas where separate power lines and data cables are impractical.

Advantage: Provides a cost-effective and reliable solution for remote installations.

Purpose: Used in smart home systems and building automation.

Function: Supplies power to smart devices (e.g., sensors, cameras, lighting) while transmitting data for centralized control.

Advantage: Simplifies the integration of smart technologies in residential and commercial buildings.

Purpose: Applied in military communication systems and remote monitoring.

Function: Provides reliable power and data transmission in harsh or critical environments.

Advantage: Ensures secure and uninterrupted operation in defense applications.

Purpose: Used in solar farms and wind energy systems.

Function: Transmits power generated by renewable sources while enabling real-time monitoring and control through data transmission.

Advantage: Enhances the efficiency and management of renewable energy installations.

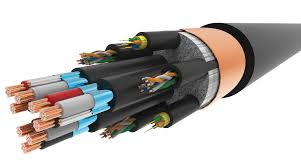

The structural design of optical-electrical composite cables typically includes the following components:

Optical Fiber Unit: Used for transmitting optical signals, usually employing single-mode or multi-mode fibers.

Power Line Unit: Used for transmitting electrical energy, typically using copper or aluminum wires.

Protective Layer: The outer sheath is usually made of polyethylene (PE) or polyvinyl chloride (PVC) materials to ensure mechanical strength and environmental resistance.

Filling Material: Filled with water-blocking or flame-retardant materials between the optical fibers and power lines to enhance the cable's waterproof and fire-resistant properties.

The technical parameters of optical-electrical composite cables typically include:

Fiber Type: Single-mode fiber (SMF) or multi-mode fiber (MMF).

Fiber Core Count: Designed with different fiber core counts based on requirements, such as 4-core, 6-core, 12-core, etc.

Power Line Specifications: Designed with different power line specifications based on power supply needs, such as 2.5mm², 4mm², etc.

Operating Voltage: Typically low voltage (e.g., 220V) or medium voltage (e.g., 1kV).

Transmission Distance: Supports different transmission distances based on fiber type and power line specifications, typically reaching several kilometers.

Optical-electrical composite cables are an efficient and economical solution suitable for scenarios requiring both communication and power supply. Their integrated design, multifunctionality, high reliability, and flexibility make them widely applicable in communication base stations, surveillance systems, smart grids, industrial automation, transportation systems, and data centers. Through proper design, installation, and maintenance, optical-electrical composite cables can provide users with stable and efficient transmission services.